Metal Additive Manufacturing

Our state-of-the-art metal additive manufacturing (Direct Metal Laser Sintering [DMLS]) machines offer high performance, reliability and, more importantly, repeatability, generating consistent parts with the same mechanical properties over and over again. Together with our a fully equipped post-processing facility we can enable the production of turnkey, ready to be used, components.

OUR MACHINES

Our suite of EOS DMLS machines is one of the largest in the UK and rapidly translate CAD data into metal components with excellent detail resolution and part quality. Market leaders in additive manufacturing technology, EOS's system, material and process parameters are intelligently harmonised to ensure reliable high quality of parts.

EOSINT M290 (12 off) – Metal Sintering Machine

Effective building volume (including building platform): 250mm x 250mm x 325mm

Laser Type: Yb-fibre laser, 400 W

Build speed (material-dependent): 2 – 8 mm3/s

Layer Thickness: 20 – 100 µm

EOSINT M280 (3 off) – Metal Sintering Machine

Effective building volume (including building platform): 250mm x 250mm x 325mm

Laser Type: Yb-fibre laser, 400 W

Build speed (material-dependent): 2 – 8 mm3/s

Layer Thickness: 20 – 80 µm

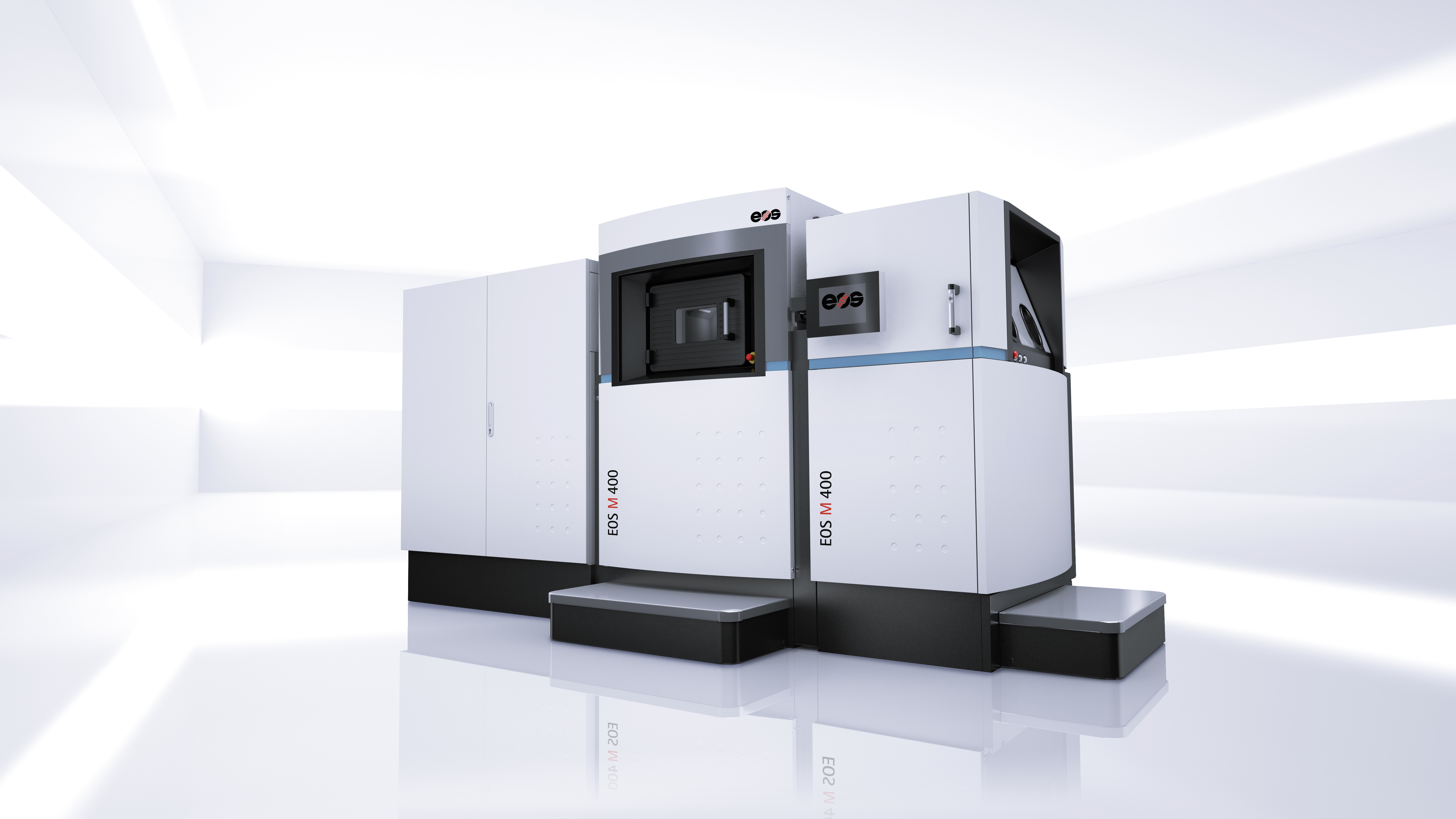

EOSINT M400 – Metal Sintering Machine

Effective building volume (including building platform): 400mm x 400mm x 400mm

Laser Type: Yb-fibre laser, 1 kW

Build speed (material-dependent): 2 – 10 mm3/s

Layer Thickness: 20 – 100 µm

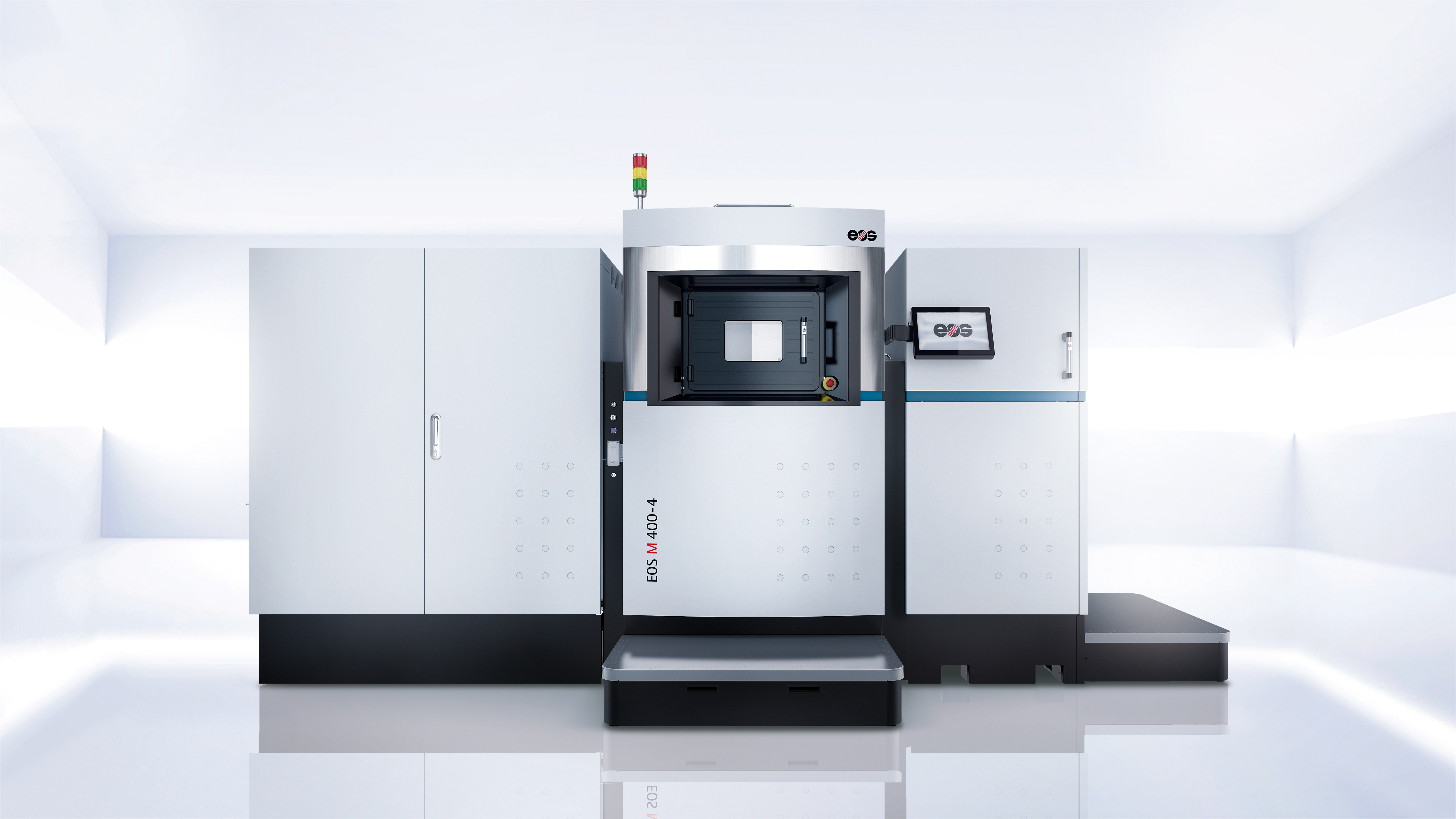

EOSINT M400-4 – Metal Sintering Machine

Effective building volume (including building platform): 400mm x 400mm x 400mm

Laser Type: Yb-fibre laser, 4 x 400 W

Build speed (material-dependent): 2 – 10 mm3/s

Layer Thickness: 20 – 100 µm

POST PRODUCTION

Our on-site facility includes:

- 2 x GF 5-Axis CNC milling machines

- 1 x DMG 3 Axis CNC milling machine

- 2 x Vibro polishers providing a better than 0.8Ra finish

- 1 x Aluminium heat treatment oven

- 1 x Vacuum furnace

- 12 Hand Finishers

- 1 x Mitutoyo CMM

- 2 x Blue light scanners

- 3 x GF EDM Machine

- 2 x Bandsaws